Product category產品類別

TECH. SUPPORT

- General Manager :

- Mr.SHIAN.XIE

- WhatsApp/Wechat :

- 13587438287

- Email :

- shianxie@126.com

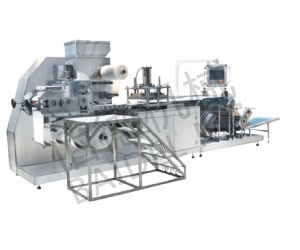

· Name of machine: fully automatic I.V. cannula dressing manufacturing and packing line

· This machine can manufacture transparent PU I.V. cannula dressing and nonwoven wound dressing.

· Normal PLC replaced by advanced motion controller system

· Each station adopts servo motor controlling, includes: basic materials peeling mechanic,

PU foil kiss cut, pad traction mechanic, pad rotary die cutting mechanic,

plaster traction mechanic, plaster rotary cutting mechanic, hot sealing,

package traction mechanic, package rotary die cutting mechanic

· Three sections of materials unwind mechanic for customer (three options): manual tension controller,

constant tension controller, full servo controlling

· Hot sealing type (two options): mold pressing or rotary sealing

Advantage1: high quality hot sealing

Advantage2: hot sealing plates are freely to change for different size

· Maximum size: 120x120mm

· It’s possible to change the rotary die for different sizes in the effective width

· According to customer special requirements, up and down packing mechanic with eye marks tracking

· According to customer special requirements, up and down packing mechanic with auto-rectifying mechanic

· Production speed up to 80-100pouches/min (based on 100x100mm)

· Total power: 13.50Kw

· Machine size (length x width x height): 3700x1180x2200mm

· Machine approx. weight: 2800Kg

· This machine can manufacture transparent PU I.V. cannula dressing and nonwoven wound dressing.

· Normal PLC replaced by advanced motion controller system

· Each station adopts servo motor controlling, includes: basic materials peeling mechanic,

PU foil kiss cut, pad traction mechanic, pad rotary die cutting mechanic,

plaster traction mechanic, plaster rotary cutting mechanic, hot sealing,

package traction mechanic, package rotary die cutting mechanic

· Three sections of materials unwind mechanic for customer (three options): manual tension controller,

constant tension controller, full servo controlling

· Hot sealing type (two options): mold pressing or rotary sealing

Advantage1: high quality hot sealing

Advantage2: hot sealing plates are freely to change for different size

· Maximum size: 120x120mm

· It’s possible to change the rotary die for different sizes in the effective width

· According to customer special requirements, up and down packing mechanic with eye marks tracking

· According to customer special requirements, up and down packing mechanic with auto-rectifying mechanic

· Production speed up to 80-100pouches/min (based on 100x100mm)

· Total power: 13.50Kw

· Machine size (length x width x height): 3700x1180x2200mm

· Machine approx. weight: 2800Kg

Previous:抱歉暫無數據